Me: This is one of those studies which will be critical if we ever choose to do a more invasive method to increase height possibly through using implants from in vitro cultured chondrocyte pellets. I have always been slightly worried over the idea of whether the cartilage the researchers can grow and develop in the cell dish can be as similar to the native cartilage and this study has given me definite proof that from using condensation of chondrocytes in cultured pellet, with the right mediums can create the real thing. This is one huge step towards showing that regrowing an entire new growth plate is possible. However it is important to remember that although a hyaline cartilage was regrown to almost perfect in vivo statues, it is not growth plate hyaline cartilage. There is still a big difference.

Here is what I always suggest the reader do: Read the 1. abstract, 2. introduction, 3. discussion, and 4. conclusion!

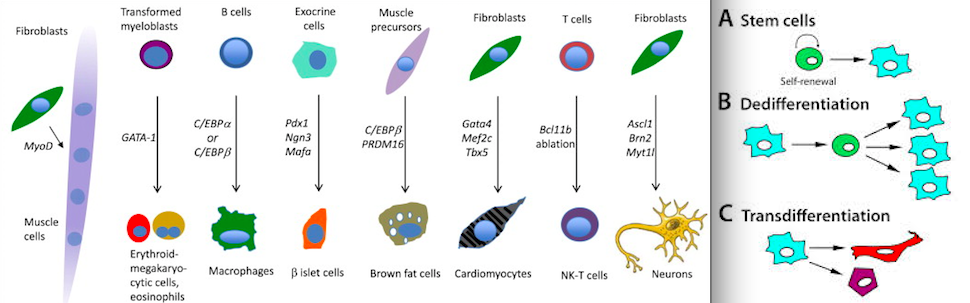

Analysis: It seems that if you extract some cartilage and try to regrow the chondrocyte in the extraction, if it is a monolayer it turns into a type of fibroblastic morphology. It starts releasing Collagen type I, instead of type II and it’s aggrecan and collagen type II core protein disappears. The process of chondrocyte condensation can actually reverse the differentiation process when in some type of cell medium. This seems to be due to the cell density being decreased in the monolayer. If you put the chondrocytes in a packed 3-D form of pellet, the chondrocyte cell density is kept high which keeps it from reversing into the differentiation process and condensing.

From the study the researchers stated that for the grown culture to be the same as the native culture, they have to be structurally and biochemically the same. The grown material was tested immunohistochemically using the different types of collegan and aggrecan. From the discusssions section “After 1–2 weeks in culture, the neocartilage shared similarities with native cartilage with regard to chondrocyte phenotype, matrix distribution and the ultrastructure of collagen fibrils.”

The last sentence of the study abstract is what made me realize that we are one more step closer to a real height increase solution…”In conclusion, hyaline cartilage engineered by chondrocytes in pellet culture, without the transformation of cell phenotypes and scaffold materials, shares similarities with native cartilage in cellular distribution, matrix composition and density, and ultrastructure.”

Note: Tyler, you said in February 2012 where you analyzed this same study that you didn’t have access to the entire study but you can find it now here on this website.

From PubMed study link HERE…

Hyaline cartilage engineered by chondrocytes in pellet culture: histological, immunohistochemical and ultrastructural analysis in comparison with cartilage explants

Cartilage engineering is a strategic experimental goal for the treatment of multiple joint diseases. Based on the process of embryonic chondrogenesis, we hypothesized that cartilage could be engineered by condensing chondrocytes in pellet culture and, in the present study, examined the quality of regenerated cartilage in direct comparison with native cartilage. Chondrocytes isolated from the sterna of chick embryos were cultured in pellets (4 × 106 cells per pellet) for 2 weeks. Cartilage explants from the same source were cultured as controls. After 2 weeks, the regenerated cartilage from pellet culture had a disc shape and was on average 9 mm at the longest diameter. The chondrocyte phenotype was stabilized in pellet culture as shown by the synthesis of type II collagen and aggrecan, which was the same intensity as in the explant after 7 days in culture. During culture, chondrocytes also continuously synthesized type IX collagen. Type X collagen was negatively stained in both pellets and explants. Except for fibril orientation, collagen fibril diameter and density in the engineered cartilage were comparable with the native cartilage. In conclusion, hyaline cartilage engineered by chondrocytes in pellet culture, without the transformation of cell phenotypes and scaffold materials, shares similarities with native cartilage in cellular distribution, matrix composition and density, and ultrastructure.

Introduction

The lack of self-healing capacity in cartilage and the considerable morbidity caused by cartilage injuries and diseases have encouraged the search for a biomedical solution for repairing or restoration of damaged articular cartilage. The recent progress in tissue engineering of cartilage includes the introduction of new biomaterials for the scaffold, development of a bioreactor culture system, and the investigation of various cell resources and use of growth factors (Cao et al. 1998; Vunjak-Novakovic et al. 1999; Potter et al. 2000; Temenoff & Mikos, 2000; Solchaga et al. 2001; Cancedda et al. 2003). However, at the present time engineered cartilage still does not satisfy the need for functional cartilage repair (Anderer & Libera, 2002).

The phenotypic instability of chondrocytes in conventional monolayer culture has been a great challenge to cartilage engineering. In monolayer culture, chondrocytes typically devolve to a fibroblastic morphology and secrete type I collagen into the matrix but lose the expression of type II collagen and aggrecan core protein (Schnabel et al. 2002). The dedifferentiated chondrocytes reverse their phenotype when condensed by continuous culture after reaching confluence (Schulze-Tanzil et al. 2002). However, it is not clear to what extent the original chondrocyte phenotype is recapitulated during the redifferentiation process (Schnabel et al. 2002). In order to produce functional cartilage, it is crucial to avoid chondrocyte dedifferentiation during the process of cartilage engineering.

Cell density is one of the critical requirements for stabilizing the chondrocyte phenotype. When chondrocytes are plated at a high density, e.g. 4 × 105 cm−2 in culture flasks, their phenotypes do not change (Ruggiero et al. 1993). Similarly, chondrocyte pellet culture has provided an in vitro model of cartilage mineralization, usually involving growth plate chondrocytes (Kato et al. 1988; Farquharson & Whitehead, 1995). There is a very great distinction in the fate of chondrocytes between the growth plate, which is progressing towards calcification, and hyaline cartilage, such as articular cartilage, which normally does not calcify (Pacifici et al. 2000). Although some studies have explored the use of pellet culture for growth plate chondrocytes and the process of mineralization, few studies have examined hyaline cartilage chondrocytes in pellet culture. Published papers using pellet culture for hyaline cartilage chondrocytes have studied the effects of exogenous agents such as bone morphogenetic protein on the chondrocyte phenotype (Stewart et al. 2000), properties of extracellular matrix (Larson et al. 2002) and bioenergetics of chondrocytes (Croucher et al. 2000; Graff et al. 2000). Presently, no previous work has used this method to engineer hyaline cartilage, and subsequently evaluated the characteristics of neocartilage. The current study, utilizing chondrocytes from a hyaline cartilage source, was designed to engineer cartilage by pellet culture. The rationale behind this method is: (1) that chondrocyte phenotype is stabilized in the pellet, thereby avoiding dedifferentiation–redifferentiation; and (2) that cartilage is engineered without additional materials such as supporting scaffolds or gels (Vunjak-Novakovic et al. 1999; Temenoff & Mikos, 2000), which introduce possible complications including immune/inflammatory responses (Cancedda et al. 2003).

The chick sternum has been widely used in chondrocyte and cartilage studies because of its easy access and unique characteristics of development (Gibson & Flint, 1985; Hirsch & Svoboda, 1998; Liu et al. 1999;Tew et al. 2000; Zhang et al. 2002). The proximal sternum calcifies between gestational days 16 and 17, preceded by chondrocyte hypertrophy. In contrast, the distal sternum maintains a hyaline phenotype and does not calcify during development (Gibson & Flint, 1985; Craig et al. 1987). Thus, only the distal part of the chick sternum was utilized in the present study. In order to be functional, the regenerated cartilage is required to be structurally and biochemically identical to native cartilage (Caplan et al. 1997). Native cartilage explants served as control in the present study. In this study, the chondrocyte phenotype was assessed with immunohistochemistry of types I, II, IX, X collagen and aggrecan. Matrix deposition and the formation of a fibril network at the ultrastrucutural level were compared between the engineered cartilage and cartilage explants taken from the same source.

Materials and methods

Pellet and explant cultures

Fertilized White Leghorn chicken eggs (Truslow Farms, Inc., Chestertown, MD, USA) were incubated at 37 °C for 16 days. The distal part of the sternum was removed from chick embryos, predigested in 0.2% collagenase (Worthington Biochemical Corp., Lakewood, NJ, USA) for 30 min, and further digested in fresh collagenase solution for 3 h. Chondrocytes were suspended in supplemented Dulbecco’s modified Eagle medium (DMEM; Biofluids Inc., Rockville, MD, USA) at a concentration of 107 mL−1. Four × 106chondrocytes in 0.4 mL of cell suspension were transferred into each 0.75-mL tube (Matrix Technologies Corp., Lowell, MA, USA). Chondrocyte pellets were formed by centrifugation at 500 g for 10 min. The culture medium was DMEM plus 10% fetal bovine serum (Hyclone, Logan, UT, USA), 50 µg mL−1ascorbate (Sigma, St Louis, MO, USA), 2 mm glutamine (Biofluids Inc.) and 0.2% penicillin/streptomycin (Life Technologies, Rockville, MD, USA). The pellets were cultured at 37 °C under a gas mixture of 95% air/5% CO2. The pellets were transferred into Petri dishes at day 3 and continued to grow for 2 weeks. The medium was changed every day for the first 3 days and every second day for the rest of the culture period. Cell viability, regularly monitored with the LIVE/DEAD® kit (Molecular Probes, Eugene, OR, USA), was greater than 90% throughout the culture period.

For explant cultures, the distal parts of sterna were diced up to about 1 × 1 × 1 mm in size. One piece of the cartilage in 0.4 mL DMEM was added into the 0.75-mL tube and centrifuged in parallel to the chondrocytes at the time of pelletting. The explants were cultured in the tubes before being moved into Petri dishes at day 3. The culture conditions and medium were identical to pellet culture.

Samples were taken at days 1, 3, 7 and 14 and fixed in 4% paraformaldehyde for 1 h. They were then washed in phosphate-buffered saline (PBS) and passed through series of sucrose gradients at concentrations of 10%, 25% and 50%, and finally embedded in OCT compound (Sakura Finetechnical Co. Ltd, Tokyo, Japan) and sectioned at 5 µm with a cryostat for histology study. Samples for electron microscopy were collected on the same time schedule as histology but fixed separately (see below).

Immunohistochemistry

The primary antibodies for immunohistochemistry were mouse anti-avian collagens type I (SP1.D8), II (II-II6B3), IX (2C2) and X (X-AC9), and aggrecan link protein (9/30/8-A-4), obtained from the Developmental Studies Hybridoma Bank, The University of Iowa (Iowa City, IA, USA). Sections were predigested with 2 mg mL−1 hyaluronidase (Sigma) for 30 min, or 1 h for type IX collagen staining (Vilamitjana et al. 1989), for the optimal penetration of antibodies. Before applying 9/30/8-A-4, aggrecan was reduced and alkylated by incubation with dithiothreitol and iodoacetic acid. After blocking with normal rabbit serum, primary antibody diluted in 1% bovine serum albumin (SP1.D8 1 : 10; II-II6B3, 2C2, X-AC9 and 9/30/8-A-4 1 : 5) was added onto the sections and incubated overnight at 4 °C. The incubation for Cy3-conjugated secondary antibody (Biomeda Biotechology, Foster City, CA, USA) was 30 min at room temperature. Sections were counterstained with 4′,6-diamidino-2-phenylindole (DAPI; Vector Laboratories, Burlingame, CA, USA). Primary antibody was replaced with PBS in the staining controls. Slides were viewed under an epifluorescent microscope and images were captured with a digital camera (Olympus BX51, Olympus America, Melville, NY, USA).

Histomorphometry

Histomorphometric analysis of aggrecan staining was performed on ten randomly selected sections of pellets and explants taken at scheduled time points, using Meta Imaging Series 4.6 (Universal Imaging Corp., West Chester, PA, USA). On each section, the measured areas, a computer-defined area of 350 × 350 pixels, were allocated as shown in Fig. 1. The average staining intensity in grey scale and the number of cells in the selected areas were calculated.

Electron microscopy

Cartilage samples were processed as previously described (McCaffery & Farquhar, 1995). Briefly, samples for electron microscopy were fixed in fixative with 3.0% formaldehyde, 1.5% glutaraldehyde in 0.1 msodium cacodylate and 2.5% sucrose (pH 7.4) for 1 h at room temperature. They were then washed three times in 0.1 m sodium cacodylate/2.5% sucrose and post-fixed at 4 °C in Palade’s fixative containing 1% OsO4. The samples were then washed, stained with uranyl acetate, dehydrated through a graded series of ethanol, and embedded in Epon. Eighty-nanometre sections were cut on a LEICA UCT ultramicrotome, post-stained in lead citrate and 2% uranyl acetate, and analysed on a Philips 420 TEM electron microscope (Royal Philips Electronics, The Netherlands) operated at 80 kV. The images were recorded and analysed with a Soft Imaging System Megaview III digital camera/software (Soft Imaging System Corp., Lakewood, CO, USA). Measurements of fibril diameter and the percentage of fibres were determined in 15 randomly selected views for the 2-week samples.

Statistical analysis

Data are presented as mean ± standard deviation and evaluated with Student’s t-test to compare the pellets with the explants at the same time point. Significance was defined as P < 0.05>

Results

The initial chondrocyte pellets, about 3.0 mm in diameter, at the bottom of the 0.75-mL tube became solid at day 3 when they were transferred from culture tubes into Petri dishes. The disc-like regenerated cartilage was about 9.0 mm in diameter and 1.0 mm in thickness by 2 weeks of culture (Fig. 2). When handling the samples for processing, the neocartilage showed similar rigidity and compression with the explant cartilage. The explants also grew and increased in size remarkably during the period of culture.

Immunohistochemistry and histomorphometry

Chondrocytes in both pellets and explants were round through the culture period. At day 1, chondrocyte density in the pellets (110 ± 17.9) was more than twice that in the explants (51 ± 9.5; P < 0.001). At day 3, a notable change in the pellets was the expansion of the intercellular space, accompanied by a gradual decrease in cell density in the pellets (80 ± 5). At day 7, cell density in the pellets (74 ± 8.5) was largely the same as in the explants (66 ± 8.4; P > 0.05), owing to the decreasing trend in the pellets and a peak increase in the explants. By day 14 cell density in the pellets (42 ± 7.8) and explants (37 ± 5.5; P > 0.05) was virtually identical.

Immunohistochemistry for aggrecan and types II and IX collagen demonstrated dynamic changes in matrix composition in both pellets and explants. Aggrecan was not seen around chondrocytes in the pellets until day 3 (Fig. 3). At day 3, the extracellular matrix in the pellets stained positively for aggrecan. Aggrecan in the pellets was mainly pericellularly stained, whereas it was uniformly stained throughout the extracellular space in the explants. The average intensity of aggrecan staining in the pellets was less than half that in the explants (Fig. 4). The average intensity of aggrecan staining in the explants steadily increased during the culture period. By day 7, aggrecan staining in the pellets showed the same pattern as in the explants and the average intensity in the pellets was equivalent to that in the explants (P > 0.05). At day 14, pericellular staining of aggrecan was the dominant pattern in both pellets and explants, and the average intensity was nearly identical.

At day 1, type II collagen was not stained around chondrocytes in the pellets, whereas the extracellular matrix in explants was uniformly positive for type II collagen staining (Fig. 5). In the pellets, type II collagen staining was seen in the extracellular space at day 3 and was consistently positive up to day 14. In comparison with the explants, type II collagen was not evenly stained at day 7, and was more pericellularly distributed at day 14.

At day 1, type IX collagen was identified in the pellets and in the explants, and showed a more diffusive staining in the extracellular matrix of the pellets as compared with the explants (Fig. 6). The staining pattern was reminiscent of type IX collagen in both pellets and explants by day 3. Type IX collagen stained more intensely in the pellets in general, although it was unevenly stained in the matrix in both explants and pellets. By day 14, staining for type IX collagen in the pellets and explants shared the same pattern of both intracellular and extracellular staining.

Type I collagen was only stained at the edge of some of the pellet and explant sections. Type X collagen was negative in both the pellet and explant, even at the end of culture (Fig. 6I,j).

Ultrastructure

At day 1, chondrocytes in the pellets were at a high concentration, and some were next to each other. However, most of the intercellular space was electron-translucent (Fig. 7a). Chondrocytes in the explants were surrounded by highly organized matrix fibrils (Fig. 7b). Chondrocytes in both pellets and explants were rounded in shape, containing conspicuous nuclei with prominent endoplasmic reticulum and Golgi apparatus indicative of healthy, actively growing cells. At day 3, deposition of granular and fibril matrix was observed in the vicinity of chondrocytes in the pellets. The fibrils and macromolecules were sparse and randomly orientated around chondrocytes. No fibril network such as in the explants was formed (Fig. 7c,d). At day 7, the number of collagen fibrils was significantly increased in the pellets and the fibrils were assembled into a network. However, the fibril meshwork was still rather loose compared with that in the explants (Fig. 7e,f). Rough endoplasmic reticulum of chondrocytes in the pellets was less prominent than at day 3. Chondrocytes in the explants, but not in the pellets, showed an increasing number of vacuoles in cytoplasm. At day 14, the average density of collagen fibrils was 0.197 ± 0.066 in the pellets and 0.253 ± 0.054 in the explants (P = 0.103). The average diameter of collagen fibrils was not significantly different (pellets: 22.11 ± 3.32 nm; explants: 23.93 ± 2.89 nm, P = 0.085). However, there was a striking difference between the pellets and explants in the manner of fibril organization and orientation (Fig. 7g,h). Whereas collagen fibrils in the explants knitted into a well-connected network, the fibrils in the pellets appeared disorganized and randomly orientated.

Discussion

In direct comparison with native cartilage, this study characterized neocartilage generated by chondrocytes deriving from hyaline cartilage in pellet culture. After 1–2 weeks in culture, the neocartilage shared similarities with native cartilage with regard to chondrocyte phenotype, matrix distribution and the ultrastructure of collagen fibrils.

It has been suggested that an important consideration in engineering functional cartilage is to follow the principles of embryonic chondrogenesis (Solchaga et al. 2001). A critical step in chondrogenesis is the condensation of mesenchymal cells, which initiates cell–cell communication and leads to the birth of chondrocytes at the early stage of embryonic development (DeLise et al. 2000). Chondrocytes in the current study were condensed from a cell concentration of 1.0 × 107 mL−1 to a semisolid pellet. Chondrocyte density in the pellets increased two-fold over that in the explants. In the pellet, the close spatial relationship of neighboring chondrocytes and limited diffusion of newly formed matrix offer a better environment for cell–cell and cell–matrix communication (Farquharson & Whitehead, 1995) and facilitate regulation of chondrocyte differentiation (Hickok et al. 1998).

Retention of chondrocyte phenotype by the pellet culture was confirmed from the highly comparable staining patterns of immunohistochemistry for type II collagen, aggrecan and type IX collagen in the pellets with those in the cartilage explants. Type II collagen and aggrecan are tissue-specific markers for regenerated cartilage (Stewart et al. 2000; Anderer & Libera, 2002; Schulze-Tanzil et al. 2002) and are essential in distinguishing between hyaline cartilage and fibrocartilage, which has been responsible previously for the failure to generate a durable cartilage repair (Nehrer et al. 1999; Hunziker, 2001). At the same time, type I collagen synthesis was almost negligible in both pellet and explant culture. This also supports our notion that pellet culture is generating hyaline cartilage and not fibrocartilage.

The in vitro environment induces a much broader range of changes in chondrocyte dedifferentiation than previously thought (Schnabel et al. 2002). Type IX collagen, one of the fibril-associated collagens, has a role in connecting type II collagen and aggrecan (Olsen, 1997). In one study, the expression of type IX collagen was lost in dedifferentiated chondrocytes after monolayer culture, and did not recover when chondrocytes redifferentiated in alginate beads and re-expressed type II collagen and proteoglycan (Zaucke et al. 2001). This makes type IX collagen a sensitive marker of the tissue culture-associated redifferentiation of chondrocytes. In pellets, type IX collagen was steadily expressed through the 14 days of culture. Even at day 1 of pellet culture, when type II collagen and aggrecan were not detectable by immunohistochemistry and electron microscopy around the isolated chondrocytes, type IX collagen was immunohistochemically detected. Except for the conventional type II collagen and aggrecan, it is imperative to introduce additional markers for chondrocyte phenotype, such as type IX collagen, to monitor the process of cartilage engineering.

Active matrix production by chondrocytes in the pellets is evident by the remarkably increased size of the neocartilage and, at the same time, a gradually decreased cell density in the pellets during the culture period. The aggrecan concentration determines cartilage compression characteristics, while collagen fibril density, orientation and cross-linking determine its tensile property (Hasler et al. 1999). Scattered matrix macromolecules were observed in the pellet cultures as early as day 3. Quantitative immunohistochemistry for aggrecan indicates that aggrecan deposition by chondrocytes in the pellets quickly reached the level of cartilage explants during the period from day 3 to day 7, and it was maintained at virtually same level as in the explants up to day 14. This involved a continuous process of reconstruction of the fibril network in the pellets, as revealed by electron microscopy. By 2 weeks, the fibril meshwork in pellets was comparable with that of the explant cartilage. Several lines of evidence suggest that collagen fibrils developing in the pellets are similar to those found in native cartilage. Fibril diameter was not statistically different between the pellets and explant cartilage. Fibril density in pellets appeared lower than in explants, but this difference was also not statistically significant. However, it should be pointed out that even at day 14 the fibril orientation in the pellets did not have the same pattern as in native cartilage. The inferiority of the fibril network organization in the pellet-generated cartilage may ultimately impact on its biomechanical properties. One possible reason for the difference between the fibril network of the pellets and explants could be that there is a lack of mechanical stimulation during pellet culture; such physical stimulation exists during embryonic chondrogenesis of the explant cartilage. Combining mechanical stimulation with pellet culture could improve the fibril network because chondrocytes adapt to mechanical forces and remodel the organization of collagen fibres accordingly (Hasler et al. 1999), and also accelerate matrix production (Zhang et al. 2002).

In the model of cartilage regeneration we have described, the collagen fibril network formed between days 3 and 7, at which time the average intensity of aggrecan in the pellets reached the level seen in explants. This observation suggests that this period may be the optimal time for modulation of cartilage formation. By day 14, chondrocyte maturation was shown in the neocartilage, as indicated by the increased cellular volume. Although the marker for chondrocyte hypertrophy, type X collagen, was lacking, chondrocytes may proceed to hypertrophy quickly at this stage (Hirsch et al. 1996). When to terminate the culture to avoid chondrocyte hypertrophy is an important issue to consider, which has not been widely discussed in the field of tissue engineering.

We note that although the current study provides data on embryonic chick cartilage, certain clinical cartilage repair protocols are likely to be based upon the growth of mature human chondrocytes. Further investigation is required to specify appropriate growth characteristics in this context.

Conclusion

Hyaline cartilage was engineered by pellet culture of chondrocytes modelled after mesenchymal cell condensation in chondrogenesis. The pellet culture system retains the chondrocyte phenotype, and the resultant cartilage is therefore produced without the transformation of cell phenotypes or the need for scaffolding materials. Further interventions, such as mechanical stimulation, may be necessary to optimize the organization of collagen fibril network in pellet culture-generated cartilage.

Acknowledgments

This study was funded by the NIA Intramural Research Program, National Institutes of Health. We thank Dr Greta M. Lee for her help in pellet culture.

Pingback: Bioengineered Cartilage Pellets And LIPUS For Longtitudinal Growth (Huge Breakthrough!) - |

Pingback: Complete List Of Posts - Natural Height Growth | Natural Height Growth