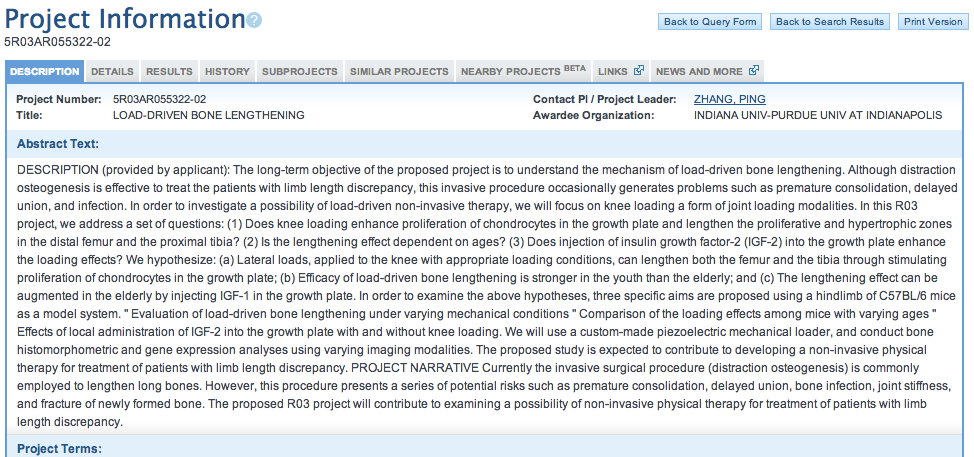

So I had said before on video and on the podcast that I had rouble understanding how to reach the right high values in Force applied and also the right high frequency for the loading to be dynamic. I had thought that there had to be some tradeoff between the two since most devices you find can’t reach those values like from Progressive Automations.

From the videos on the Progressive Automations you realize the large, heavy powered Actuators which extend or retract by a DC power moves and strokes rather slowly never reaching even the 5 Hz value we saw in the studies with either the rat hindlimbs or the rat elbows which causing humeral and ulna lengthening. I was thinking about this problem last night when I realized what was the problem, and the issue was that I was probably rethinking about the original loading device using by Yokota and Zhang in an incorrect way.

Here is how we can resolve the Loading Vs. Frequency problem. We have to reduce the frequency down to a certain level maybe 1 Hz for the device to even allow for load.

From the progressive automations website, we see that the usual types of applications of the linear servos was to hold something up, like a 48″ TV. When you want to hide a tv in a dresser, you click on a remote and the actuator moves down and the TV drops down out of sight. When you want the TV, you hit another button and the actuator pushes the TV back up. This is how the actuators are supposed to work, by providing a constant, static (NON-DYNAMIC) loading value.

Assuming the TV is 100 lb, then the mass of the TV is calculated to be around 100/2.2= 45.36 kg. That is the mass of the TV. remember that the units of lb and kg are completely different, one is for a fundamental intrinsic property while the other is for a derived function depending on the environment, specifically the gravitational force the mass exerts at a certain direction. In SI units it is 9.81 m/s^2 while in US units it is 32.2 ft/s^2. For the actuator to push the TV up, it’s loading which is a force value in units of Newtons (kg*m/S^2) must be higher than the force of the TV pushing down on the actuator, which is just it’s weight.

These conceptual understanding shows that for the LSJL machine to even have a loading value in units of force, Newtons, it must hold at least for a extended time, of a static constant value.

The reason is because to calculate the vector function F we must have a mass, which is easily found, and another function, acceraltion which is a vector so we have to get the direction as well.

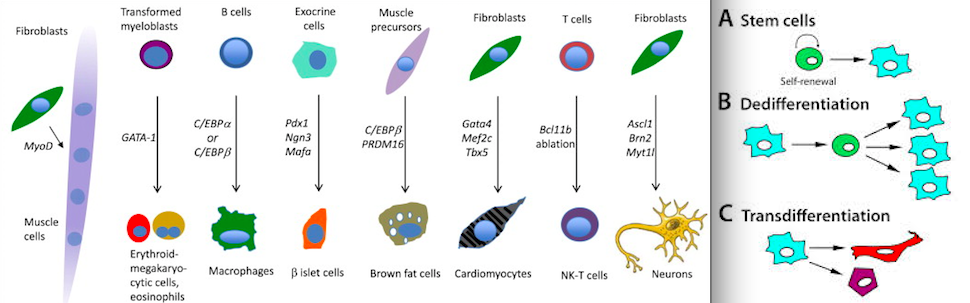

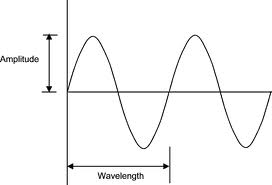

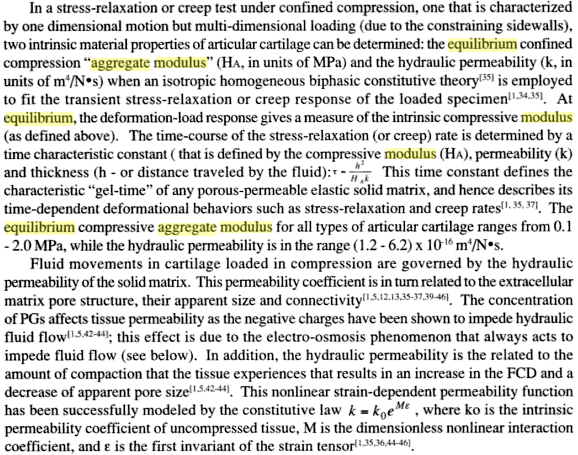

Taking a short tangent into waves and vibration elementary physics we remember that we can treat the dynamic movement of one of the clamp ends as a ossilator which ossilates between the middle set point moving between a set distance away from the middle set point, (say 3 cm in -x and x direction) in the imagined arbitrarily assigned x-y-z axis system. We say that when this simplied system of an ossicilator is modeled using simple mathematics.

Taking a short tangent into waves and vibration elementary physics we remember that we can treat the dynamic movement of one of the clamp ends as a ossilator which ossilates between the middle set point moving between a set distance away from the middle set point, (say 3 cm in -x and x direction) in the imagined arbitrarily assigned x-y-z axis system. We say that when this simplied system of an ossicilator is modeled using simple mathematics.

It can also be viewed as a pendulum system if desired but an ossilator is a more accurate model. The distance the peizoelectric load side moves if graphed on just a x-y axis plane where the x is time and y is distance, would be a sine wave since we assume the position of the side starts from the initial set point (value of zero). So the value of the distance versus time looks like the figure on the right.

For us to go from distance to acceleration, we have to take the derivative of the x=f(t) function twice. is a=del^2(x=f(t)/dt^2

If we remember from calculus, the derivative of the sine wave is the cos wave. but when we take the derivative of the cos wave we get back to the sine wave. This shows that at certain times of the dynamic moving loading device, it has no acceleration, specifically when the flat piezoelectric plate which is the clamping side is at the set point. which means the force it is applying is really 0, so there is no loading.

Conceptually that means that when the clamping moving in a sinusoidal, oscillatory movement reaches the bone to hit it, it is at its greatest value of acceleration in terms of magnitude. That means that if we increase the frequency speed in units of Hz, we should increase the loading value at the point of contact. The key is to make sure the piezoelectric material in contact with the epiphysis/bone is a hard material that has a high young’s modulus which will not deform. The impact of the hit

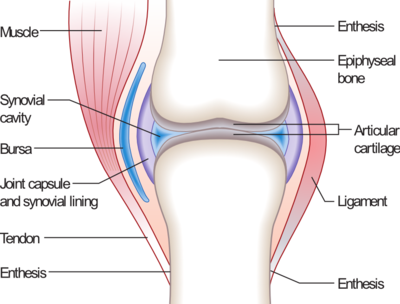

The main problem conceptually now is where we are really supposed to clamp or not. When talking about units in Hertz, the real physical units are “the rate of the occurence or phenomena over a specific time duration, 1 second”. When in the Articles Zhang says they had 5 Hz (Source) that means the the device hit the mouse synovial joint 5 times in one second. From a picture of the device, it seems that the device is not automated with some form of feedback loop device. It was probably operated on by a graduate student who had to clamp down using their hands.

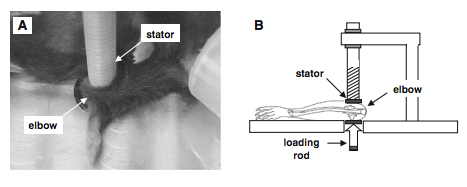

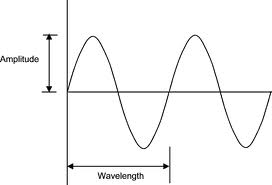

From the PubMed study entitled “Elbow loading promotes longitudinal bone growth of the ulna and the humerus” by Yokota and Zhang I took a clip of the picture below which shows the schematic of the original device used for loading. Also took the section titled “experimental design”

Experimental design

In the loading group, mice were mask-anesthetized using 1.5% isoflurane and received loads to the left elbow in the lateral-medial direction with the custom-made piezoelectric mechanical loader. Loads were 0.5 N at 5 Hz and given for 5 min per day for 10 days (Fig. 1a, b). The lateral and the medial sides of the ulna and humerus were in contact with the loading rod and the stator, respectively.

We chose a forelimb configuration that made the right angle (90�) between the ulna and the humerus, since in this position the forelimb was relaxed and stably immobilized (Fig. 1c). To position the elbow properly for loading, the lower end of the loading rod and the upper end of the supporter (nylon screw) were designed to form a pair of semi-spherical cups. The olecranon process and coronoid process of the ulna together with the ulnar tuberosity, and medial and lateral epicondyles of the humerus were confined in the cups. The tip of the loader had a contact surface of 3 mm in diameter. To avoid a local stress concentration between the elbow and the loader, both the loading surface and supporter were covered with silicon rubber. The right elbow was used as a sham loading control (contralateral control), which was placed under the loader with no dynamic loading. In the age-matched control group, the same procedure was applied without application of lateral loads.

I was introduced to this Patent Idea HERE when I first proposed building this device which showed that the University researchers had in 2005 already filed a patent. In the patent Yokota with Tanaka stated that …”The magnitude of the mechanical load is oscillated and is applied periodically for a short durations of time.” This suggests that the oscillatory movement is not the easily mathematically graphed behavior of sinusoidal functions like using a sine or cosine function. It seems that the device is supposed to be applied to the bone, held in that position for a short while and then removed, and the processes repeated. This would make more sense since we saw from HeightQuest that the procedure involves using a C-Clamp and holding the clamp position for about 30 seconds before letting go and doing it for only about 5 minutes.

Me: From the Description section of the patent we find that they describe the patent using these figures. So these are the proposed values for the device to be built.

- Frequency: 2 Hz

- Load: 100 Newtons laterally

- PiezoElectric Material Used: Electrochemical materials such as a polypyrrole polymer and a polythiophene polymer can be used as an artificial-muscle-like actuator

For mice… Frequency: 2 Hz, Loading: 0.5 Newtons,

Interesting, the big problem now is that I don’t know how or which equation to use to calculate the force of that will be generated from the type of device we will build. In the testing, the equation they used is sigma*w*t. The device proposed involves a motor that moves in rotation like the piston you see in the wheels of old style trains which have an overall 1 dimensional movement created from rotational energy. This proposed patent for a device is a feedback mecahnism with a way to tell teh device how much force to use at what frequency as well as collect the amount of electrical energy and potential as well as force loaded down in data form for analysis later. At this point, I have not read over the entire patent but the device is quite advanced and sophisticated enough that I would need at least 2 electrical engineers to put everything together within a reasonable time frame if we just tried to use the principles of the device themself.

Implications: This post shows that I was too naive and optimistic in thinking that building a LSJL device for human use would be easy because I had not considered the effect of also the piezoelectric material for electrical stimulation utility. What I have finally concluded at least at this point is that the 5 Hz that Yokota or Zhang was talking about was probably for per minute basis than per second. Hz is supposed to be for per second basis, but if we consider the fact that the oscillating loads were only done for about 5 minutes a day and that there was only 5 Hz used, that meant one loading and removal took 1 minute each. This would coencide with the LSJL method Tyler proposed which is to clamp down on the bone for 30 seconds, let go for another 30 seconds, and repeat the process. At this point, it would suggest that we do not need a frequency of 5 Hz but actually 1/60 or about .016 Hz. The loading is also very small at the suggested level of 100 Newtons. All I can conclude after this long post is that we will need to really sit down to do the right types of calculations to figure out the values for how to load the bone, how big the area of the piezoelectric device must be, and whether we should set up a type of recording and feedback system to the device to optimize for efficacy.

32, 132 and the torque applied to the band 228, 328 around joint 22 can be chosen so that fluid flow would be induced in bone without disturbing any function or structure of joint 22. For apparatus 20, 122 that may be driven by air pressure approximately 40 kPa (5.8 psi) was needed to provide 0.5 N to murine elbows in the second exemplary study discussed below. Assuming that 100 N is used to press a lateral wall of a human knee joint, 51 kPa (7.4 psi) is required for a 50 mm in diameter bladder 32, 132. For instance, pump 136 may be a micro air pump driven at 6-24 NDC with 180 g weight (available from Sensidyne, of Clearwater, FL).

For apparatus 220, 320 driven by tensioning the circumferential band 228, 328, FIGS. 1 C and ID, the tensile stress in the band, σt, is: σt = Pr/t where P = pressure, r = radius of a supporter, and t = thickness of a band. With P = 51 kPa, r = 50 mm, and t = 3 mm, σt is estimated as 0.85 MPa. Since the required force to induce σ , is σtwt with w = width of a band 228, (50 mm), motor 236 with 5-mm torque arm needs to generate about 0.64 Νm. For example, a gear motor (3363020, available from Igarashi Motors, of St. Charles, IL) having dimensions of 20 mm x 24.5 mm x 29 mm (110 g) can generate up to 1.0 Νm at 12 V.

Electrochemical materials such as a polypyrrole polymer and a polythiophene polymer can be used as an artificial-muscle-like actuator 328 for apparatus 320. These polymers can be stretched or compressed through ?on formational changes inducible in an electrical field. Actuators can be formed in any shape, for example, belts, and it can easily generate strain of 10 % and stress above 20 MPa with a small amount of electricity. For example, a conductive polypyrrole polymer (available from EAMEX Co., of Osaka, Japan) with a cross-sectional area of 50 mm (width) x 3 mm (thickness) can generate 189 Ν (Hara, S, Zama T, S S, Takashima W, Kaneto K. 2003. Highly stretchable and powerful polyprrole linear actuators. Chemistry Letters, 32:576-577.).

A first exemplary experimental study compared bone formation in murine ulnae exposed to mechanical loading with bone formation in nonloaded control murine ulnae. Twenty female C57BL/6 mice (14 weeks old) with a body weight of approximately 20 g were used for the study. Each mouse was mask-anesthetized using 2% isoflurane. The mechanical loading was applied with piezoelectric loader 400 (FIGS. 4A and 4B) to right arm 402a (See, Tanaka, S.M., Alam, I.M. and Turner, CH. (2003) Stochastic resonance in osteogenic response to mechanical loading. FASEB J, 17, 313-314.) for 3 minutes per day for three consecutive days to elbow 408 through a lateral medial direction as shown in FIG. 5 A. Left arms were used as nonloaded control specimens. Loading force 416 was sinusoidal at 2 Hz with a peak-to-peak force of 0.5 N, as shown in FIG. 8A. In order to avoid local stress concentrations between joint 408 and loading element 414, the surface of loading element 414 was covered with a silicon rubber sheet (not shown).

The exemplary mechanical loader 400 used for the study includes an electro-mechanical loading structure and instrumentation. Specifically, structure 430 supports loading element 414 and cantilever 446, coupled to structure 430, supports loading screw 412. Loading screw 412 has an adjustable displacement relative to loading element 414. Specimen 402 to be loaded is positioned between screw 412 and element 414 and screw 412 is adjusted to contact specimen 402. Data acquisition board/command generator 436 provides a command signal to piezo driver 434, which in turn drive piezoelectric actuator 432. Actuator 432 is mechanically coupled to loading element 414 and provides the desired mechanical load commanded by command generator 436.

Instrumentation of mechanical loader 400 includes strain gauge 444 mechanically coupled to cantilever 446 and electrically coupled to strain gauge conditioner 438 and data acquisition board 436. Strain gauge 444 provides monitoring and control of the mechanical load applied to the specimen. Displacement sensor 448 is coupled to cantilever 446 and measure the variation in displacement relative to lever 450 coupled to loading element 414. Switch 442 selectively electrically couples data acquisition board 436 to signal conditioner 440 which is electrically coupled to displacement sensor 448. Switch 442 also selectively electrically couples data acquisition board 436 to electrode 452. Electrode 452 is placed in contact with specimen 402 for measuring the electrical potential of specimen 402 relative to the ground of loader 400.

All mice were, given an injection of 0.05 ml saline containing 1% calcein 2 and 6 days after the last application of mechanical load, and ulnae 404a/b were harvested 13 days after the loading. Harvested ulnae 404a/b were fixed in 10% formalin for 2 days. After dehydration by immersion in a series of efhanol solutions, ulnae 404a/b were embedded in methyl methacrylate. Transverse sections 405a/b (FIGS. 6A-6C) 50 um in thickness were cut at 2.5 mm distal from elbow 408 using a diamond wire saw, and ground with sand paper (#400) to about 20 um in thickness. The sections were examined with a fluorescence microscope.

Using a semiautomatic digitizing system (Bioquant available from R&M Biometrics, of Nashville, TN), three morphometric parameters were determined for the periosteal surface of ulnae 404a/b, including mineralizing surface (MS/BS, %), mineral apposition rate (MAR, um/day), and bone formation rate (BFR/BS, um3/um2/year), where MS = sum of the length of the double-labeled perimeter and half of the single-labeled perimeter, BS = total length of the perimeter, MAR = average radial distance 418 (FIG. 6C) between the two labels per day, and BFR = MS/BS x MAR x 3.65 (Hsieh, Y.F. and Turner, CH. (2001) Effects of loading frequency on mechanically induced bone formation. Journal of Bone and Mineral Research, 16: 918-924).

Streaming potentials were measured as a voltage generated between electrode 452 on a periosteal surface of an ulnar midshaft and a common ground for loading system 400. The periosteal surface connected to the electrode was dissected free of muscle and was always kept moist with a saline solution. A 16-bit data-acquisition board operated by a computer was used to record streaming potentials at a 250-usec interval. In order to examine statistical significance in the histomorphometric data, ANOVA analysis (using Statview, Version 5.0, available from SAS Institute Inc., of Cary, NC) was conducted with a significance level at p < 0.05.

Bone histomorphometry with fluorescent cacein-labeling revealed that elbow loading significantly stimulated bone formation. Cross section 405a (FIGS. 6B and 6C) of ulna diaphysis 2.5 mm distal (16% of ulnar length) to elbow 408, clearly showed double labeling 418 on a periosteal surface with a sinusoidal loading for 3 minutes per day for 3 days on the elbow, as compared with cross section 405b of unloaded control ulna. Three bone morphometric parameters, MS/BS (mineralizing surface, p=0.0002), MAR (mineral apposition rate, p=0.045), and BFR/MS (bone formation rate, p=0.012), were significantly increased by elbow loading , as shown in FIGS. 7A-7C. The increase in MS/BS, MAR, and BFR/MS was 3.2-fold, 3.0-fold, and 7.9-fold, respectively.

Streaming potential, induced by a coupling between ion flux and fluid movement, is a good indicator of strain-induced fluid flow in bone (Beck, B.R., Qin, Y.X., McLeod, K.J., and Otter, M.W. (2002) On the relationship between streaming potential and strain in an in vivo bone preparation. Calcif Tissue Int, 71, 335-343). In response to joint loading at 2 Hz with 0.5-N force, harmonic potentials were observed that were synchronized with the mechanical stimuli, as shown in FIGS. 8A-8C Longitudinal axis loading to ulna 404b, shown in FIG. 5B, one of the conventional bone loading methods to induce strain in cortical bone and bone formation (Tanaka et al., 2003; Robling, A.G. and Turner, CH. (2002) Mechanotransduction in bone: genetic effects on mechanosensitivity in mice. Bone, 31, 562-569), also generated a streaming potential with a magnitude on the same order as lateral joint loading (FIG. 5 A). The histomorphometric data demonstrates that lateral joint loading requires a lower magnitude of loading force (0.5 N peak-to-peak) to induce bone formation than the conventional axial bone loading methods which requires over 1 N peak-to-peak force (Robling et al., 2002).

Conventionally a joint has been considered as a shock absorber that protects bone from impact loading (Voloshin, A., Wosk J., Brull M. 1981. Force wave transmission through the human locomotor system. J Biomech Eng, 103:48-50). In the first exemplary study, however, joint loading showed a significant increase in bone formation on a periosteal surface of diaphysis cortical bone. It has been well-recognized that the osteogenic responses can be induced by bone strain in vivo (Rubin, C.T. and Lanyon, L. E. (1985) Regulation of bone mass by mechanical strain magnitude. Calcified Tissue International, 37:411-417; Turner, C. H., Forwood, M. R, Rho, J. Y., and Yoshikawa, T. (1994) Mechanical loading thresholds for lamellar and woven bone formation. Journal of Bone and Mineral Research, 9:87-97) and fluid flow in vitro (You, J., Yellowly, C. E., Donahue, H. J., Zhang, Y., Chen, Q., and Jacobs, C. R. (2000) Substrate deformation levels associated with routine physical activity are less stimulatory to bone cells relative to loading-induced oscillatory fluid flow. Journal of Biomedical Engineering, 122:387-393). Since streaming potential is an indicator of fluid flow in bone, the data on streaming potentials and bone morphometry demonstrate that joint loading can induce fluid flow and stimulate bone formation without causing strain in cortical bone